You’ve found what seems like the perfect spandex fabric for your project. It has the right color, the right weight, and a great hand feel. But before you commit to a bulk purchase or start cutting into it, have you ever stopped to ask a crucial question: will this fabric hold its shape over time, or will it bag out and lose its elasticity?

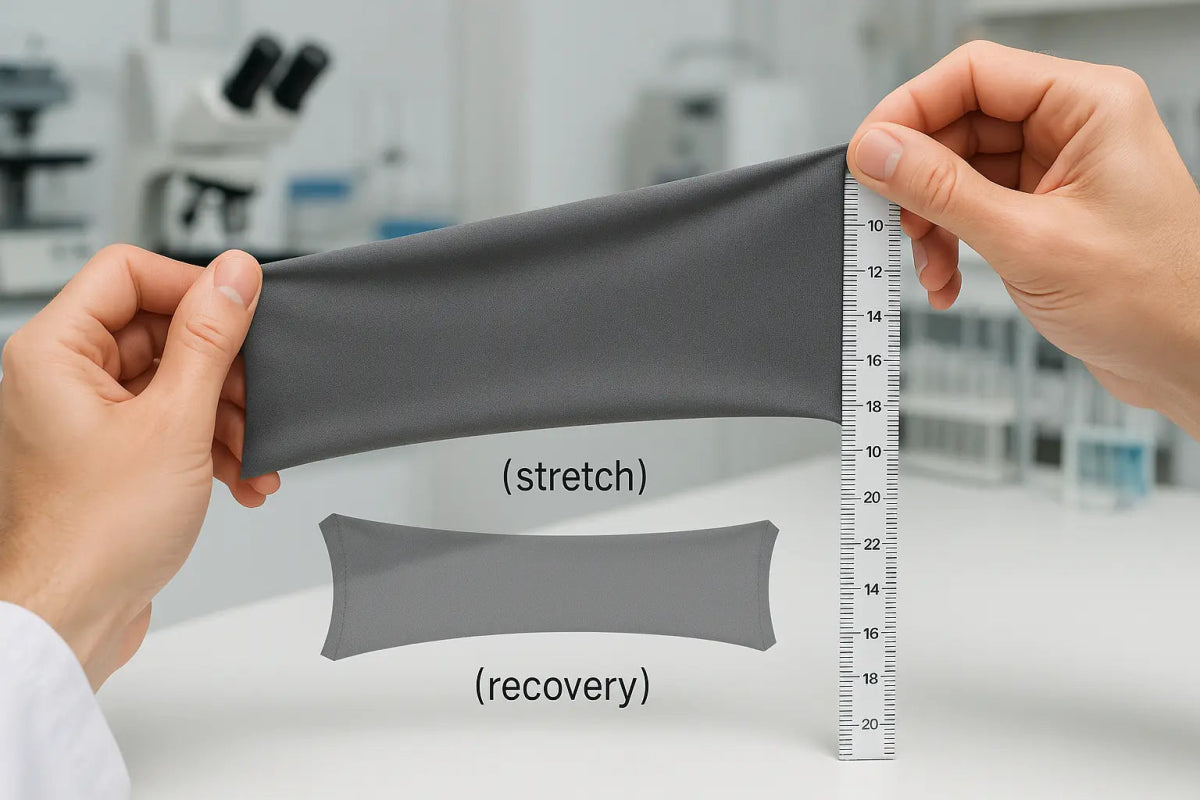

The difference between a high-quality, long-lasting spandex garment and one that quickly loses its shape isn't a matter of luck. It's a matter of science, specifically how the fabric performs under stress. The two most important metrics for evaluating spandex performance are stretch and recovery, and they can be measured with simple, yet highly effective, tests.

This comprehensive guide will demystify the essential concepts of fabric stretch and recovery. We'll show you why these properties are so critical, provide you with easy-to-follow, step-by-step instructions for performing your own tests, and explain how to interpret the results to ensure you're always choosing a fabric that offers the best possible performance and durability.

Why Stretch and Recovery Matter: The Pillars of Spandex Quality

To understand a spandex fabric, you must first understand these two core concepts. They are the twin pillars that support the entire structure of spandex performance.

What is Stretch?

Stretch is a fabric’s ability to elongate under tension. It's the maximum length a fabric can reach before its fibers start to break or become permanently damaged. In the context of activewear and other stretch fabrics, stretch is quantified as a percentage, telling you how much the fabric will expand. For instance, a fabric with 50% stretch will stretch to 1.5 times its original length.

- Why it matters: The stretch percentage determines a garment's range of motion and overall fit. A high stretch percentage is crucial for athletic gear that must accommodate complex, dynamic movements like squats or yoga poses. A fabric with insufficient stretch will feel restrictive and uncomfortable.

What is Recovery?

Recovery is the fabric’s ability to return to its original shape and dimensions after being stretched. It's the "snap-back" you feel when you release the fabric from tension. High-quality spandex is known for its excellent recovery, which is what prevents garments from becoming baggy or saggy in high-stress areas like the knees, elbows, or waistband.

- Why it matters: Good recovery is the key to garment longevity. A fabric with poor recovery will permanently stretch out, leading to a loose, unflattering fit that degrades the garment's appearance and functionality over time. A garment is only as good as its recovery.

A spandex fabric can have high stretch but poor recovery, which means it will stretch a lot but won't snap back. This is the hallmark of a low-quality fabric. A great spandex fabric has both high stretch and excellent recovery.

The Key Tests: Measuring Stretch and Recovery

There are standardized, professional methods for testing fabric, but you don't need a lab to get meaningful results. We'll show you two methods: a simple, at-home test for quick assessments and a more detailed version that gets you closer to professional standards.

Test 1: The Stretch Percentage Test

Goal: To measure the maximum elongation of a fabric.

Simple At-Home Method (for buyers and sewers):

- Prepare a Sample: Get a piece of fabric at least 10 inches long by 4 inches wide. This test is most effective on a swatch that hasn't been sewn.

- Mark the Start: Lay the fabric flat and use a ruler to mark a 10-inch segment. You can use pins, tape, or a marker. This is your baseline.

- Stretch the Fabric: Grasp the fabric at each end of the 10-inch segment. Gently and evenly pull the fabric until you feel a significant resistance. Do not pull so hard that the fabric or seams break.

- Measure the Stretch: While holding the fabric stretched, measure the new length.

- Calculate the Percentage: Use this simple formula: (New Length - Original Length) / Original Length * 100.

Example: If your 10-inch segment stretches to 15 inches:(15 - 10) / 10 * 100 = 50% stretch

- Repeat for Both Directions: If it's a 4-way stretch fabric, repeat this entire process on both the lengthwise and crosswise grains to ensure consistent stretch.

Interpreting Your Results:

- Low Stretch (20-30%): Suitable for comfort stretch in woven fabrics, like denim. Not enough for activewear.

- Mid-Range Stretch (40-60%): Great for comfortable everyday leggings, t-shirts, and casual wear.

- High Stretch (70-100%+): Essential for high-performance activewear, compression wear, dancewear, and swimwear.

Test 2: The Recovery Test

Goal: To measure the fabric’s ability to return to its original length after being stretched. This is the most crucial test for assessing long-term durability.

Simple At-Home Method (for buyers and sewers):

- Prepare a Sample: You'll use the same 10-inch marked swatch from the stretch test.

- Apply a Stretch: Stretch the fabric by a predetermined amount. A good starting point is to stretch it to about 50% of its maximum potential (so, for a fabric that stretches to 15 inches, stretch it to 12.5 inches). Hold it stretched for a full minute to simulate wear.

- Release and Measure Immediately: Release the fabric and immediately measure the length of your marked segment. A great recovery fabric will snap back to near its original 10-inch length.

- Check for Residual Stretch: Lay the fabric flat, do not pull or manipulate it, and let it rest for 10 minutes. Then, measure the segment again.

- Interpret the Result: The closer the final measurement is to your original 10-inch length, the better the recovery. A fabric that recovers to 10.25 inches is excellent. A fabric that recovers to 11 inches or more has poor recovery and will likely lose its shape quickly.

Standardized Industrial Testing: A Deeper Look

While the at-home tests are great for a quick check, textile manufacturers and quality control labs use more rigorous, standardized methods to ensure consistent quality. The most common standard for stretch and recovery is the ASTM D2594 method.

How it works (for context):

- A fabric swatch of a specific size is placed in a tensile testing machine.

- The machine uses clamps to hold the fabric and a controlled force to stretch it to a specific percentage (e.g., 50% stretch).

- The fabric is held in this stretched state for a defined period.

- The machine then releases the tension, and the fabric's length is measured at specific time intervals (e.g., immediately, after one minute, after one hour).

- The results provide precise metrics on both the elongation percentage and the recovery percentage of the fabric.

This level of detail is critical for manufacturers who must guarantee their products meet strict performance standards, especially for high-end activewear, medical compression gear, and industrial applications.

Why You Should Pay Attention to the Numbers

Understanding the results of these tests empowers you to make better choices, whether you're a professional or a passionate consumer.

For Manufacturers and Bulk Buyers

- Ensuring Product Quality: By testing fabric from your suppliers, you ensure that every roll you buy meets your brand's quality standards. This is essential for building a reputation for durable, high-performance products.

- Preventing Returns and Complaints: A garment that loses its shape after a few wears will lead to unhappy customers and high return rates. Proper testing minimizes this risk, protecting your brand's reputation and your bottom line.

- Matching Fabric to Application: The results of these tests tell you if a fabric is truly suitable for its intended purpose. A fabric with 50% stretch is not going to work for a high-impact compression garment that needs 90% stretch and superior recovery.

For Consumers and Home Sewers

- Informed Decisions: Understanding these tests allows you to look beyond a fabric's color and price. You can now recognize that a more expensive fabric with 80% stretch and excellent recovery is a better investment than a cheap fabric with 50% stretch and poor recovery.

- Predicting Garment Longevity: By performing a simple test, you can get a good idea of how your finished garment will hold up over time. A fabric with excellent recovery is a sign that your hard work will result in a durable, long-lasting piece.

- Achieving the Perfect Fit: Knowing the stretch percentage is key to choosing the right pattern size. Many patterns for knits specify a minimum stretch percentage. By measuring your fabric, you can ensure it meets the pattern's requirements for a perfect fit.

Interpreting the Results: What Good and Bad Looks Like

|

Stretch Percentage |

Recovery |

Quality & Performance |

Common Uses |

|

High (70-100%) |

Excellent |

Superior Quality & Performance |

High-end leggings, compression wear, swimwear, dancewear |

|

Mid-Range (40-60%) |

Good |

Good Quality & Performance |

Everyday leggings, t-shirts, casual sportswear |

|

High (70-100%) |

Poor |

Poor Quality |

Garments that will stretch out, sag, and lose shape quickly |

|

Low (<40%) |

Good |

Limited Performance |

Woven fabrics with comfort stretch (e.g., denim) |

Frequently Asked Questions (FAQ)

Q1: What's a good stretch percentage for leggings? A1: For comfortable everyday leggings, a 40-60% stretch is good. For high-performance leggings that need to be opaque and supportive for workouts like running or squats, you should look for fabrics with a 70-100% stretch and excellent recovery.

Q2: What causes a fabric to have poor recovery? A2: Poor recovery is often a sign of low-quality spandex fiber. Inexpensive spandex yarn can break down under repeated stretching or exposure to heat during the manufacturing process, losing its elastic properties. The quality of the companion fiber (nylon or polyester) also plays a role in supporting the spandex.

Q3: Can I test a finished garment for stretch and recovery? A3: Yes, you can. Stretch a specific area, like a waistband or the knee, and measure its length before and after a period of rest. However, this is less reliable than testing a new swatch because a finished garment has already been worn, washed, and stretched.

Q4: How do I know if a fabric is a 2-way or 4-way stretch? A4: You can easily test this at home. A 2-way stretch fabric will stretch significantly in one direction (usually crosswise) but have little to no stretch in the other. A 4-way stretch fabric will stretch in both the lengthwise and crosswise directions. You should perform the stretch and recovery tests on both directions for a 4-way stretch fabric.

Conclusion

Understanding spandex fabric stretch and recovery is more than just a technical exercise; it's a fundamental aspect of quality control and a powerful tool for making informed decisions. By taking a few moments to perform these simple tests, you gain the power to predict a garment's performance, durability, and lifespan.

Whether you're a brand committed to building a reputation for excellence or a consumer who demands quality from their purchases, measuring stretch and recovery is the key to separating a great fabric from a subpar one.

At SpandexByYard.com, we believe in transparency and the power of informed choices. We provide detailed specifications on our high-quality spandex fabrics, including their stretch percentages and recovery properties, so you can confidently choose a fabric that will pass your tests with flying colors. Explore our collection and discover the difference that quality makes.